HOME / Hardware / FBI-Gauge Features

- Supports line and surface observation, as well as Reduce man-hours and cost of settings point observation

- Extremely lightweight sensor

- Can be used in electromagnetic environments and places where fire is strictly prohibited

- Sensor can be freely attached to fit different measurement conditions

- Single sensor capable of performing strain, tem-perature, and a variety of other measurements.

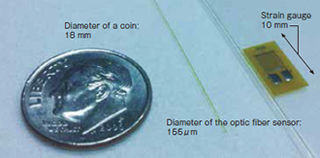

Thin optic fibers with a diameter of 155μm can be set in extremely narrow gaps.

They are also ideal for measuring the strain of curved surfaces. (Minimum bending radius=10mm)

- Measuring the strain or temperature in an electromagnetic environment

- Measuring an object with multiple measurement points that make it difficult to install the gauge

- Checking the temperature distribution of a tower that is tens of meters in height

- Measuring the inside of narrow gaps

- Conducting measurements when the weight of the connection cable for the strain gauge is too heavy

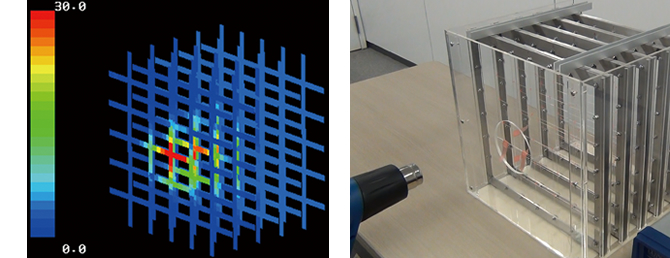

As the photo to the left shows, there is a problem with point measurement -- Tons of connection cables are needed when there is a large number of gauge channels. The use of lightweight optic fibers is the perfect solution for conducting measure-ments across numerous channels.

Optic fibers are thin and lightweight, allowing you to freely design a layout that fits your installation needs. As the figure to right shows, installation in the air makes it possible to visualize the tempera - ture distribution in space.

About FBI-Gauge

FBI-Gauge is an optic sensing system that detects minute light reflections (known as Rayleigh scattering) produced by glass molecules in an optic fiber subject to a variable wavelength laser beam (1,510~1,570 nm).

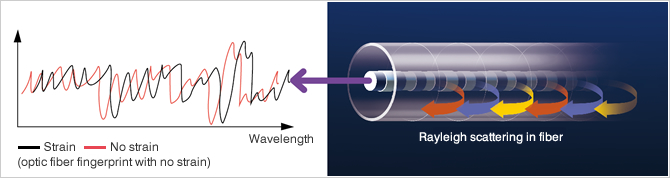

Unique optic fiber fingerprints and frequency offset due to strain

Minute density variations occur in the glass molecules in optic fiber. These are uniquely different for every optic fiber. The density variations cause discrepancies in the refractive index and these in turn govern the light wavelengths subject to Rayleigh scattering. The sum total of density variations along the length of an optic fiber is known as the optic fiber fingerprint, which effectively means that the same wavelength will always produce the same reflections provided that the optic fiber remains intact. In the event of st rain occurring on the optic fiber, the reflected wavelengths will be offset at that particular point. FBI-Gauge uses a before and after comparison of reflected light patterns to determine the location and degree of strain at points along the optic fiber.

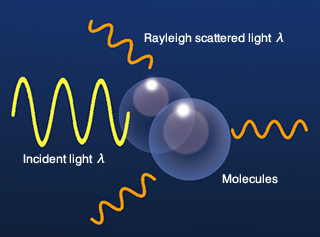

FBI-Gauge detects reflected light in the form of Rayleigh scattering in the optic fiber.

Scattering normally refers to random dispersion of light caused by collisions with particles such as molecules in the air. The phenomenon known as Rayleigh scattering is associated with very small particles of the order of 10% of the light wavelength. A brilliant blue sky is the result of Rayleigh scattering of sunlight due to molecules in the air. Rayleigh scattering in optic fiber, meanwhile, is caused by collisions with glass molecules.

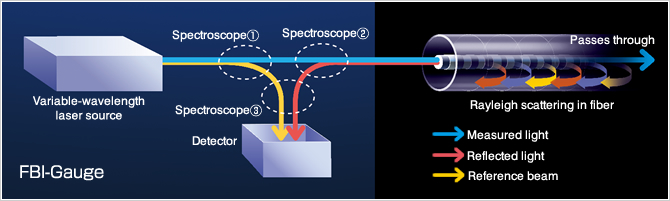

OFDR detection and measurement with FBI-Gauge

The FBI-Gauge system uses OFDR (Optical Frequency Domain Reflectometry) to analyzereflected light with in optic fiber.

The OFDR processing sequence for Rayleigh scattered light is illustrated below.

- An incident beam with periodically changing wavelength (within the range 1,510~1,570 nm) is projected into the optical path.

- Spectroscope [1] splits the light into two: a sensing beam directed into the optical fiber and a reference beam sent directly to the detector.

- The sensing beam travels the length of the optic fiber and is scattering, producing reflected light.

- The reflected light passes through spectroscope [2] and is sent to the detector.

- Spectroscope [3] merges the reference beam with the reflected light. The detector then analyzes variation in light intensity due to interference.

- A Fourier transformation is performed on the measurement data to determine the scattering frequency at each point along the optic fiber.

- The wavelengths of the optic fiber's unique fingerprint are compared to the observed wavelengths in order to determine the offset ⊿ν.

Change in ⊿ν is governed by the type of optic fiber and the incident light wavelength and is expressed as a linear relationship. ⊿ν can be used to calculate the extent of strain as well as temperature changes.

Comparison with Extensometer and Strain gauge

In this example, we compare an extensometer and strain gauge in a tensile test on a test piece. The extensometer and strain gauge generate results at the same degree of precision. While the extensometer and strain gauge use a single sensor at a single location, optic fiber enables continuous measurement over the entire fiber length.

System overview /

Features /

Post software /

Distributed strain measurement /

Use of FBI-Gauge in the automotive industry

Use of FBI-Gauge in industrial facilities and in the construction industry /

Product seminars