HOME / Hardware / GAPGUN:System Overview

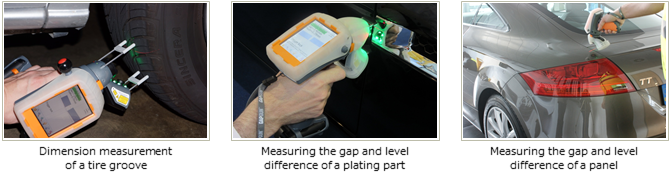

GapGun uses a laser to measure cross-sections without contact.

Combining unmatched measurement speed, exceptional ease of use, portability and toughness, GapGun allows you to inspect level differences, gaps, arcs, edge discontinuities, countersinks, seal potions, angles and so on with the ultimate level of measurement quality.

What’s more, users can be guided through the process based on a measurement plan with predetermined measurement points, while measurement results can be instantly transferred to a PC and output as an inspection result report.

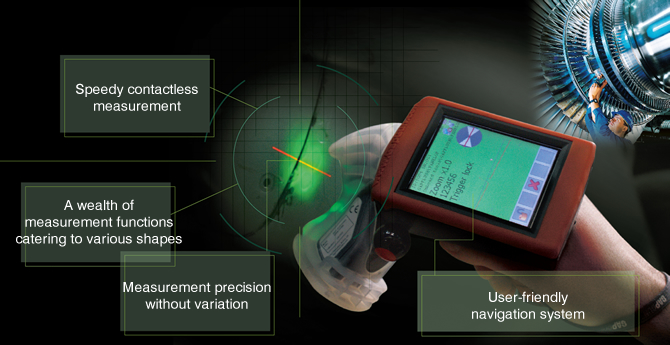

As a laser is used to perform measurement, speedy, contactless measurement is possible, and without having to worry about scratching the measurement target.

In addition to gaps and level differences, GapGun instantly measures a wide variety of shapes, such as the circumference and radius of an arc or the dimensions of a rivet.

GapGun is able to stably measure slight gaps and level differences that have proven difficult for conventional tools such as calipers. Sensor heads tailored to different measurement objects can also be easily replaced.

By creating a measurement plan on a PC and synchronizing it with the device, instructions for measurement points will be displayed on the handheld screen. Along with being displayed on the screen, measurement results are automatically saved and output as a report in the designated format.