HOME / Hardware / FBI-Gauge Use of FBI-Gauge in the automotive industry

FBI-Gauge is a strain and temperature sensing system that uses optic fibers for the sensors. Measurements can performed continuously along the optic fiber, allowing for continuous line and surface observation over a wide area, as well as point observation. The sensor part of the FBI-Gauge does not use electricity, which means the system can also be used in an electromagnetic environment.

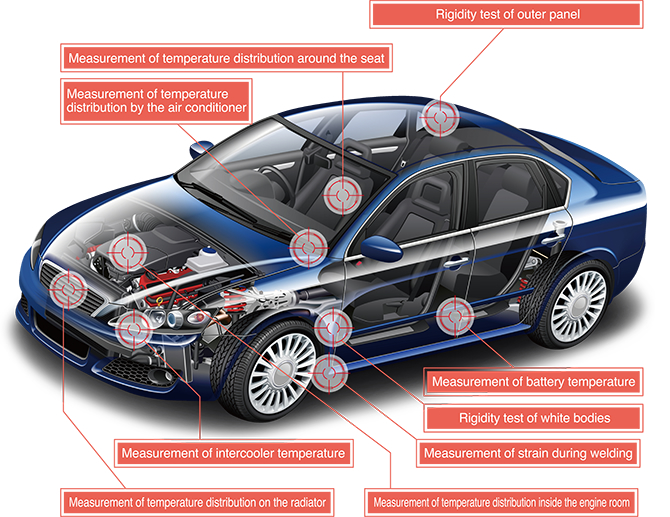

Measurement of temperature distribution on the radiator

Measurement of temperature distribution inside the engine room

Rigidity test of outer panel

This setup is ideal for comparing the results of an outer panel rigidity test with the CAE results.

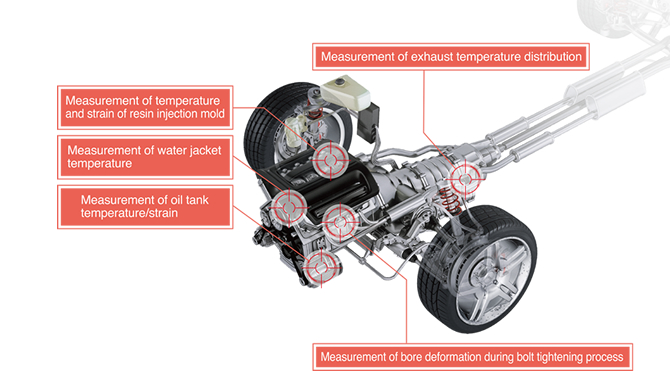

Measurement of exhaust temperature distribution

The use of a single fiber eliminates the need for time synchronization and other tasks. Thus, the FBI-Gauge can also be used to compare the timing of multiple parts.

Rigidity test of white bodies

With the traditional point observation, there was an unavoidable gap in skill between skilled workers and inexperienced workers. There was also the troublesome of task of checking whether the sensor was attached to the position where the strain is at its peak. Distribution measurement with the FBI-Gauge allows you to not only locate the peak strain afterwards, but also confirm the strain gradient.

Measurement of bore deformation during bolt tightening process

The FBI-Gauge is ideal for measuring strain of precision parts, such as the bore and bearing at the time of bolt tightening. The extremely thin size of the optic fiber sensor (155 μm) allows it be installed in many different places.

In addition the use of a single fiber sensor to perform measurements also allows for time synchronization, making it possible to check changes in strain while the bolt is being tightened.

System overview /

Features /

Post software /

Distributed strain measurement /

Use of FBI-Gauge in the automotive industry

Use of FBI-Gauge in industrial facilities and in the construction industry /

Product seminars