HOME / Software / MPS-RYUJIN : New features

Rigid-fluid coupled analysis function

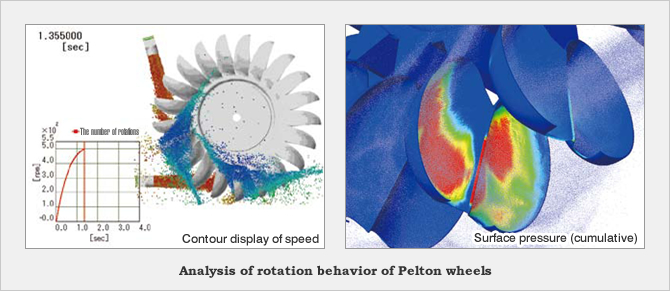

Analysis of the rotation behavior of Pelton wheel runners This is an example of rigid-fluid coupled analysis with a rotating Pelton wheel via the modeling of the wheel using polygons and water injected from the nozzle.

The RYUJIN analysis allows the pressure applied to the turbine surface, the number of rotations, torque, and other values to be calculated.

It also enables analysis of how running water interferes through analysis of the rotation behavior using several nozzles, which was difficult with the conventional method.

Highly viscous solver function

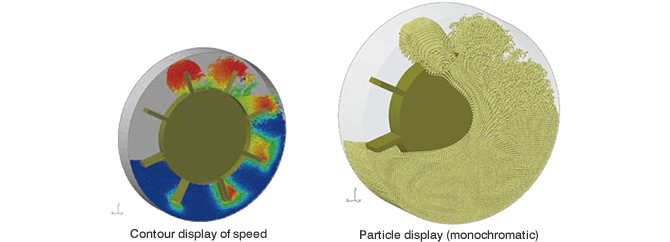

Analysis of gear stirring using highly viscous oil With the conventional MPS method any increase in viscosity resulted in smaller hourly intervals, which then required a remarkably long time for the calculation.

MPS-RYUJIN has considerably reduced the time required for analyzing highly-viscous fluids by calculating the viscosity using the implicit method.

This enables, for example, the stirring resistance of oil that has become more viscous in a cold area to be calculated.

Function that examine atmospheric and negative pressures

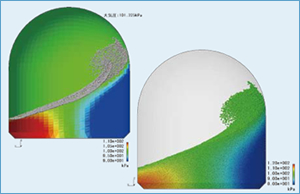

Tank sloshing analysis through examining atmospheric and negative pressures The conventional MPS method could not examine negative pressure as the calculations defined the pressure on the liquid level as 0.

MPS-RYUJIN supports fluid analysis that examines both atmospheric and negative pressures through the development of a unique proprietary pressure calculation algorithm.

This has then enabled sloshing analysis that analyzes the structural loads caused by not only positive pressure but also negative pressure.

Pressure calculation function with volume changes taken into account

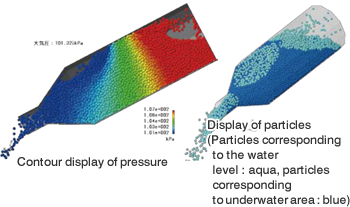

Runoff analysis from bottles The conventional particle method defined a particle-free space as a vacuum.

MPS-RYUJIN enables pressure changes due to volume changes to be taken into consideration with spaces enclosed by structural walls or particles.

Applying the pressure of the closed space on the liquid level can represented bubbles.

Dynamic load balancing function

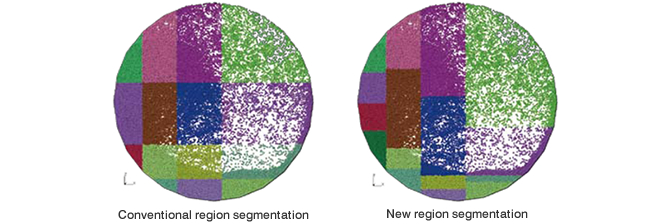

Parallel computing with the conventional particle method did not support changes in the computational load with each area associated with changes in flow rate.

The latest version utilizes more flexible region segmentation and dynamic load balancing that can handle changes in the computational load associated with swift flows, thus resulting in its parallel performance having been spectacularly improved.

Product overview /

Moving Particle Semi-implicit (MPS) theory /

Fluid analysis solver functions

Pre and post processing /

Sample analysis scenarios /

New features /

Product seminars